Solid day of work in the garage today.....not really missing work at all today either.

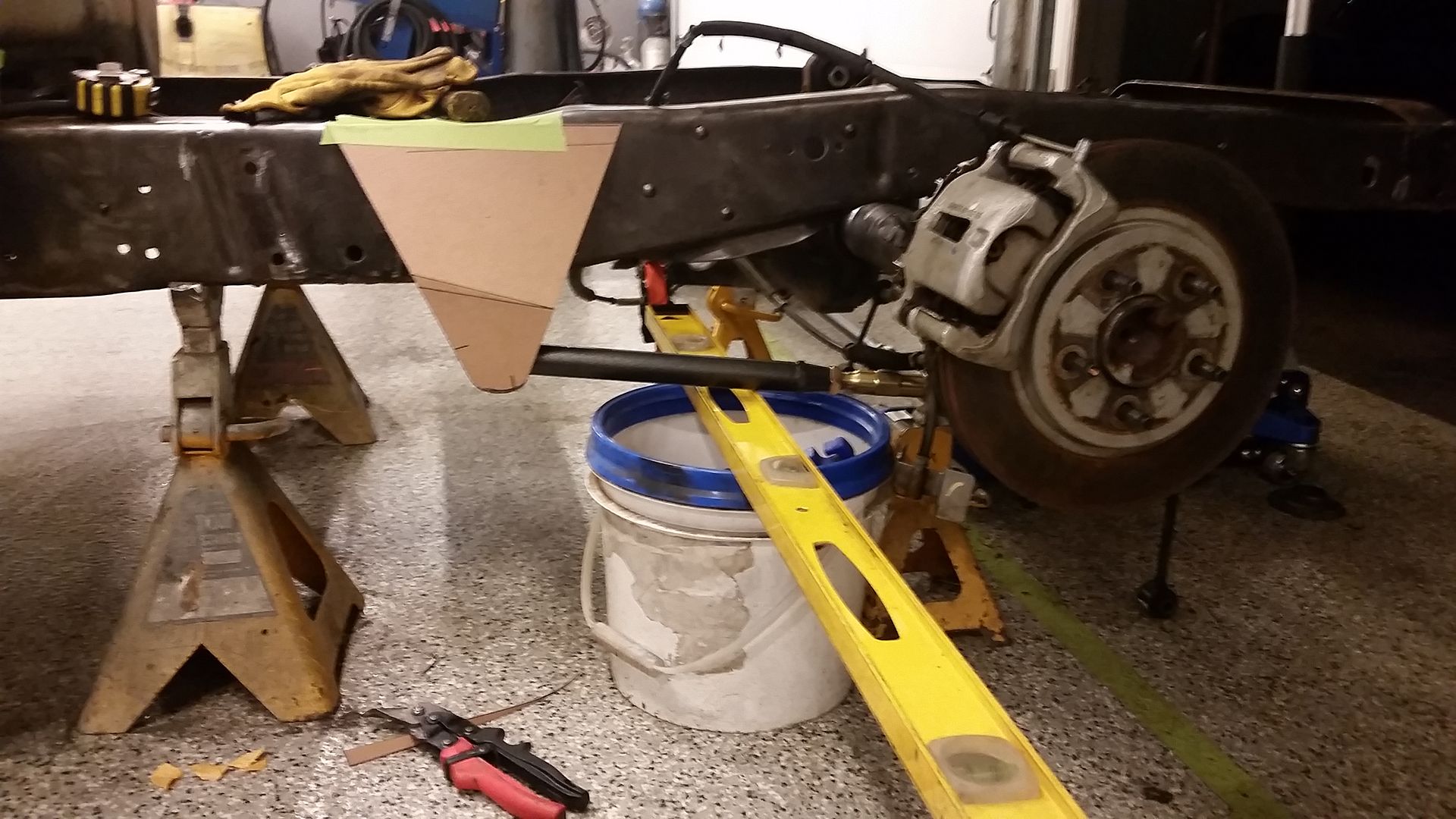

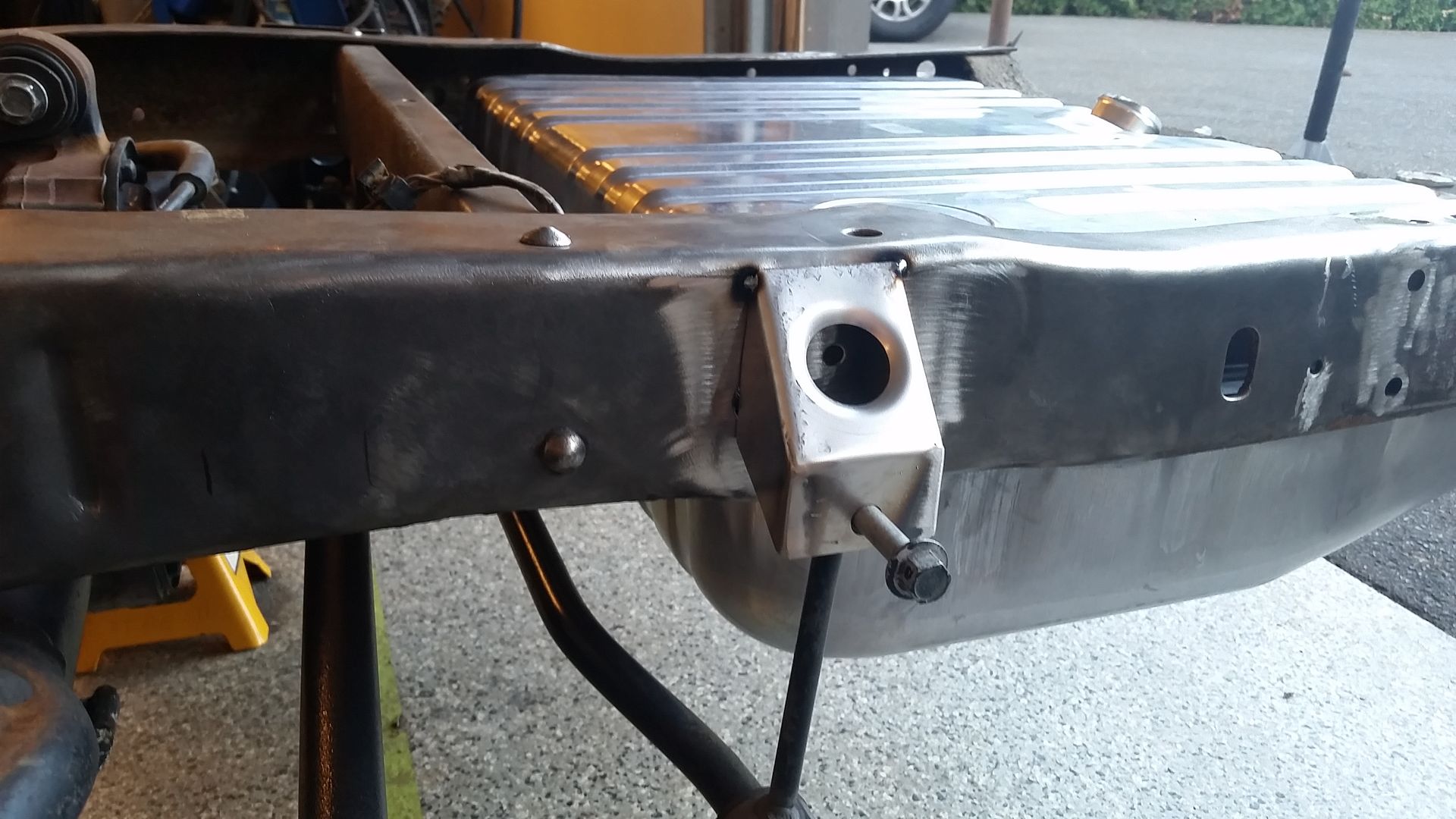

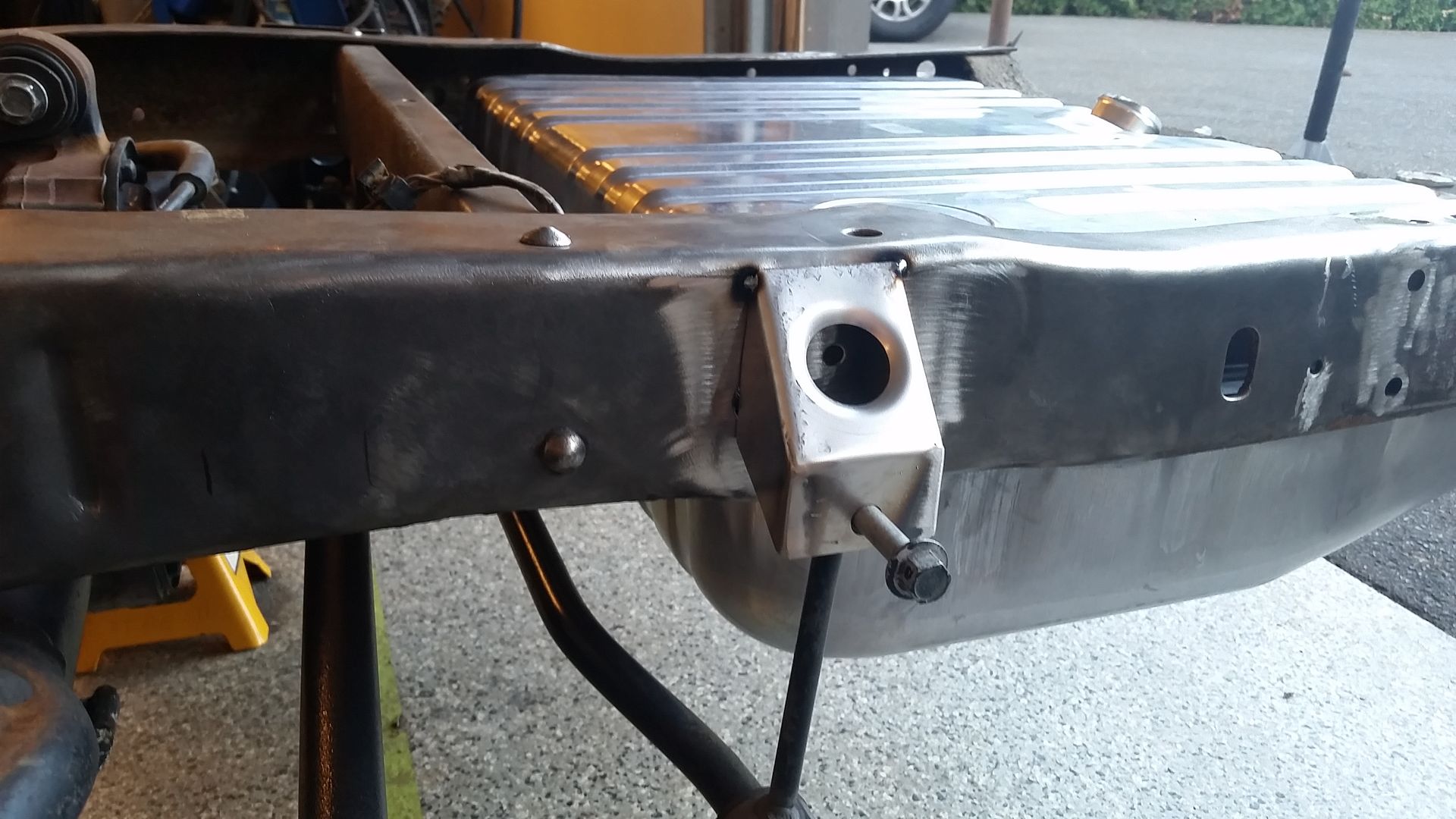

Got the upper link mount built. Tied it into the factory crossmember. Not too sure If I am going to run some tubes down to the inner frame rails or not. It is plenty beefy, all 3/16".

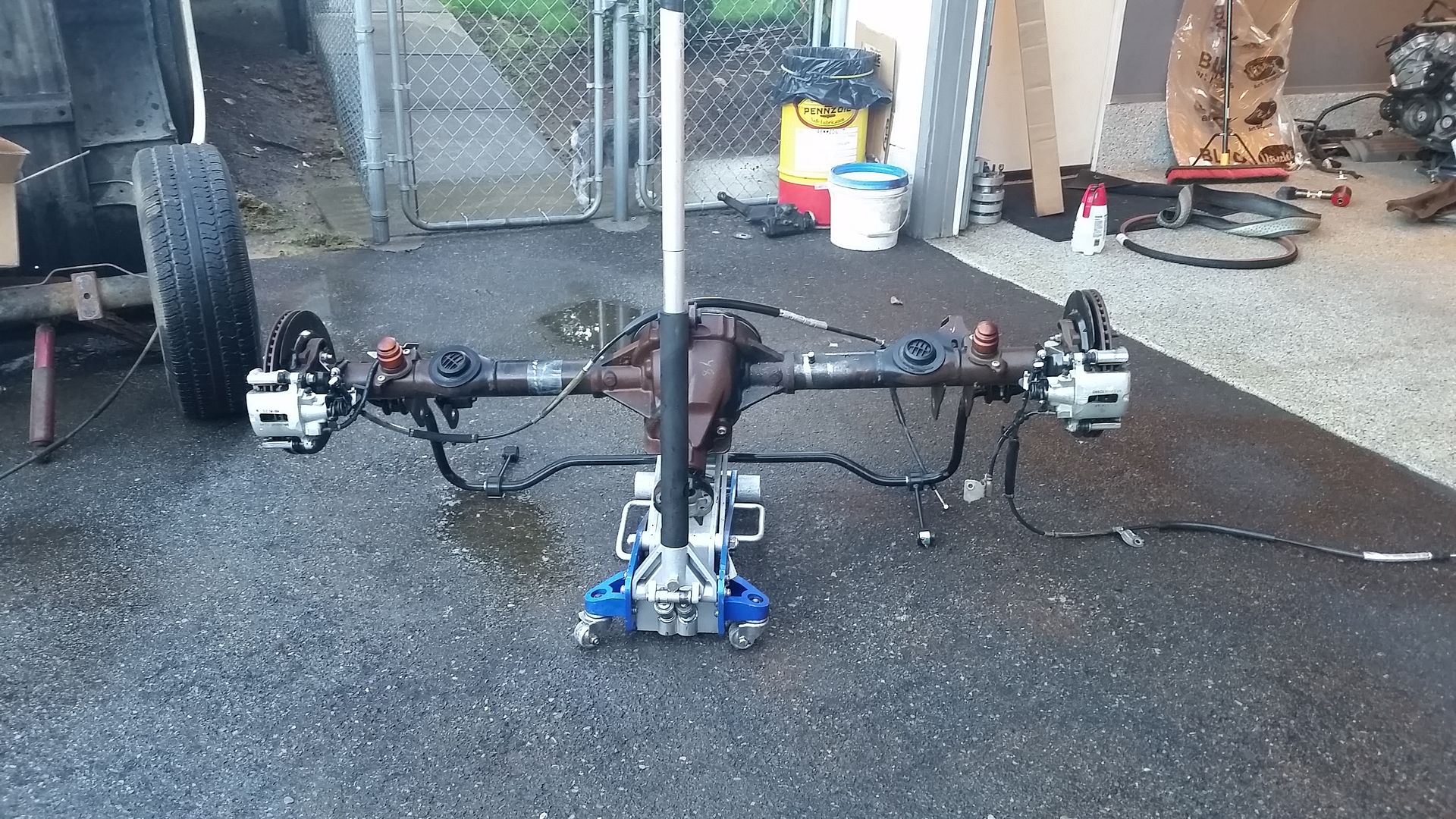

Plan coming together on the emergency brake cables as well. Amazed that this is going to work out..

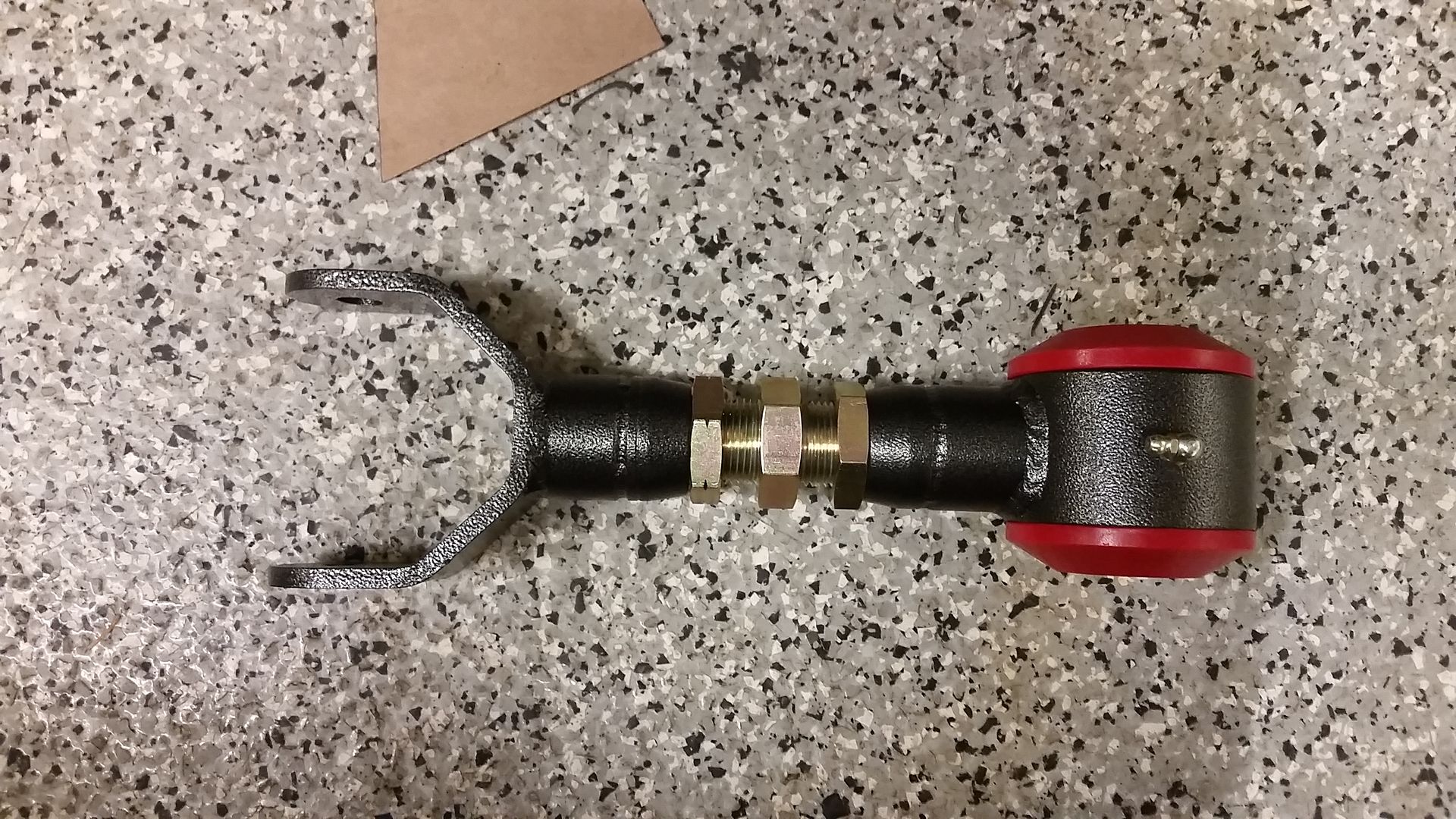

So, swapped the cables side to side to get the lengths right and they are just like I had them built to fit the truck. Cut an access through the upper link mount on the passenger side and the front and built this mount for the cables to attach to the factory setup.

Of course, more dimple dies.

With that done I needed to get the rear sway bar mounts done but before I could do that I needed to get the tank mocked up to make sure that the swaybar clears the tank. So more rivets to come out.....son of a bitch there are a lot of rivets on this thing.

Got those and the stock shock mounts off the truck and pulled the rear most crossmember. Cut out the sides of the frame just enough to get the tank to slide in and slid in the rear crossmember. Going to try and keep the tank as far back as I can for clearance in front of it for fuel, suspension and sway bar stuff.

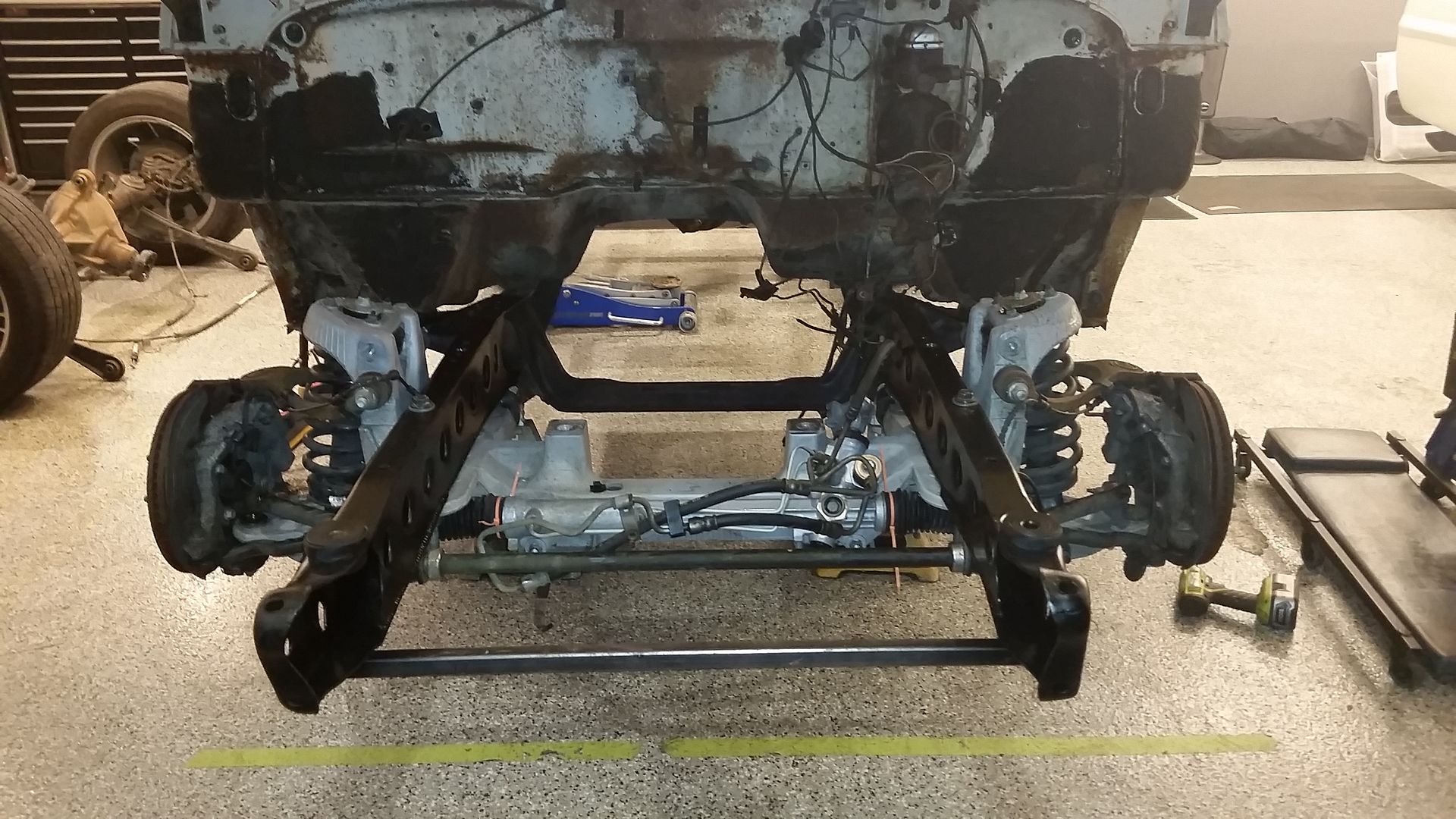

So with that done, I can get to work on sway bar mounts. Believe it or not I had a tougher time with these than just about anything else today. Just could not get them to look how I wanted but they turned out ok.

Driver side..

Passenger side, trying to leave room for shock mounts. Ordered coilovers for the rear last night but after measuring more this morning I think they are going to be too short, they only have 3.5" of travel.

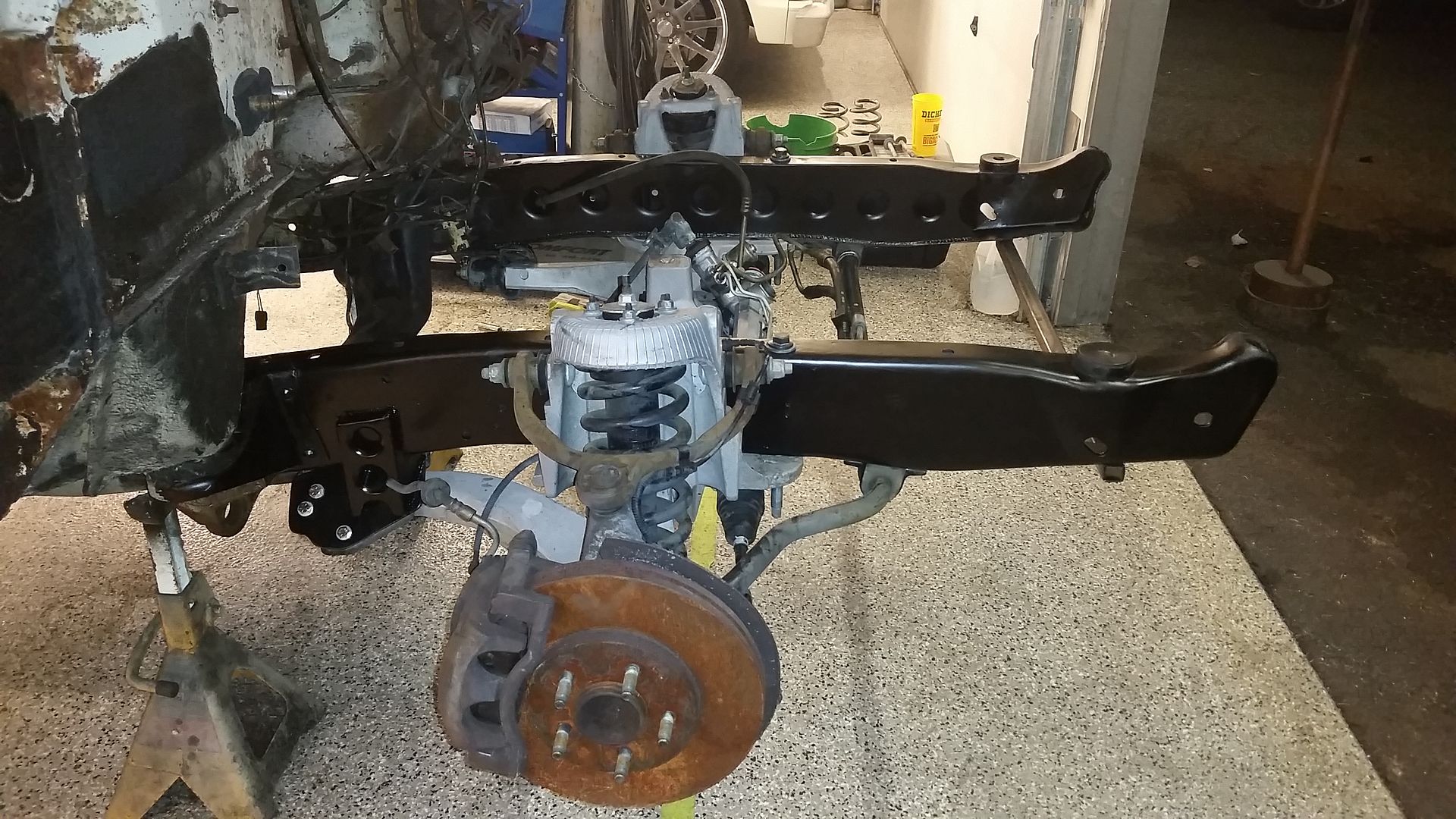

Front NAAKE coilovers showed up today as well as the camber adjustment kit for the crwon vic frontend. Really hoping that the rear shocks and springs get here tomorrow, I would love to finish weld out the rear saturday and get shocks mounted.

Waiting on motor mounts as well, should be here tomorrow too.

Sean